With the market for sustainable packaging rapidly expanding, packaging companies need to systematically screen the value chain for opportunities to innovate.

Packaging and processing industry

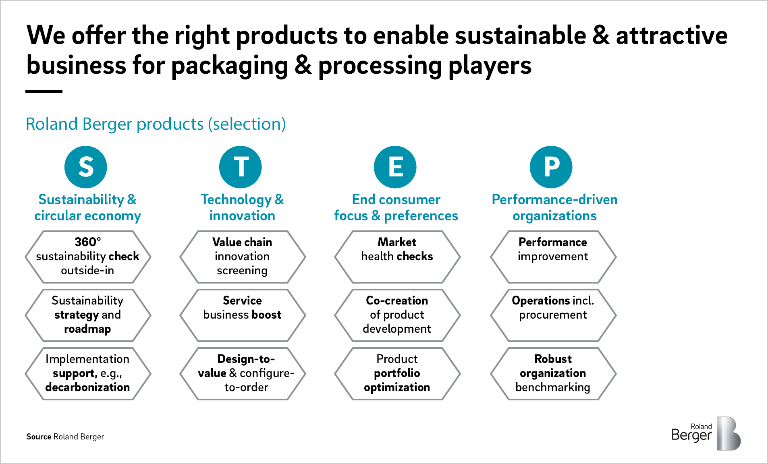

Navigating the complex and rapidly changing packaging and processing market with our STEP framework

"Our STEP framework helps companies navigate the market and set strategic priorities for sustainable growth."

The packaging and processing industry has seen significant growth in recent decades. Today, packaging plays a vital role in modern life. It ensures the hygiene and safety of products; it protects goods during transport; it provides space for necessary consumer information; and its design plays an important role in our purchasing decisions. Similarly, the demand for processed food, beverage and pharmaceutical products has grown continuously. This is the result of increasing wealth and desire for processed goods and the development of the secondary and tertiary sector in emerging markets where people have less time available to aim for self-sufficiency.

However, equipment suppliers and converter companies in the packaging and processing industry are facing a raft of challenges and rising uncertainty. Covid-19 has changed consumer buying habits and demand, while economic upheaval and political instability mean that firms need to be nimble. The demand for and regulatory push towards sustainability, the emergence of digital innovations, the changing behavior and end consumer preferences (especially coming out of Covid-19), and the need for high performing organizations are key trends that test industry players' ability to adapt and offer opportunities for value capture for those that are successful.

Roland Berger regularly publishes on the packaging & processing industry and the associated opportunities for companies. Below you will find a selection of our current publications containing the latest research findings, expert assessments and future scenarios.

Our STEP framework to navigate complexity in the industry

We developed our STEP framework to highlight the key trend clusters that are reshaping the packaging and processing industry. The framework supports companies in the packaging and processing industry in establishing a comprehensive set of strategic priorities for sustainable growth.

The four key trends include sustainability & circular economy, technology & innovation, end consumer focus & preferences and performance-driven organizations. We typically work with our clients to review their current business activities in these four dimensions to identify areas for further opportunities.

"Sustainability is at the heart of the packaging industry. Companies must embrace the principles of the circular economy to succeed."

Sustainability & circular economy

Consumers and governments around the world have been increasingly demanding action to curb climate change and environmental pollution. The packaging and processing industry, viewed by many as a significant contributor to the problem, finds itself under pressure to respond. Sustainability impacts the entire value chain, from the machines being used to the suppliers of the raw materials. Companies that transform these areas in line with the new paradigm will reap the benefits. These include: capturing new market opportunities and competitive advantages, increasing waste reduction and achieving improved profitability. Efficient resource and recycling management are particularly important.

Roadmaps to material portfolio changes, new innovation models and closer relationships with customers and suppliers, and building circular economy loops and infrastructure are not always easy to define while also trying to maintain efficiencies. They demand a holistic understanding of the value chain, material, processing technologies and consumer and customer preferences. Becoming more sustainable can often tie into major changes on an organizational level as well. As a first step companies need to define a holistic ESG strategy and roadmap to reach clearly set targets.

Technology & innovation

Technology advances are changing how consumers interact with packaging and helping businesses become more efficient. Technology and innovation - from smart and active packaging to new design and materials - are also enabling the packaging industry to respond to sustainability and changing consumer demands for health, safety, convenience, individuality, etc. Technology and innovation advances are not just to be found in the packaging itself, but also in the processing. New packaging calls for new equipment in some cases; economic factors such as labor, supply chain constraints and cost pressure call for new ways of working (remote and virtual service, automation, software and more). This certainly creates opportunities and new revenue pools, but it also makes it difficult for firms to navigate decisions to create, capture and defend value, where some technologies will be winners or will lead to industry disruption.

"Bio-based plastic can provide environmental benefits over fossil-based plastic, but it must be sourced and managed responsibly."

End consumer focus & preferences

Market players are increasingly focusing on end consumers and their preferences. This is due to the innovation pattern, as innovation is ever more driven by the consumer who is looking to interact differently with the packaging. For example, consumers demand lighter and more flexible packaging - a process known as down-gauging. Food safety, health/wellness and traceability are other growing concerns, which have to be dealt with alongside regular e-commerce activities. In the future, the ways in which consumers interact with packaging will further evolve, creating the need for improved performance attributes, proximity and convenience to the individual, and more sophisticated branding to generate interest. In addition, new packaging formats must be safe, connected and engaging, as well as sustainable. Currently, many incumbents face the challenge of continuously innovating to maintain competitive edge.

Performance-driven organizations

The increasing uncertainty in the market is a call for companies to establish themselves as performance-driven organizations. Businesses have to respond to the need for robustness, flexibility and greater efficiency (often driven by cost pressure). The Covid-19 crisis has driven home the need to build robust supply chains and production network. Moreover, new materials and technological developments, such as printed RFID chips, are emerging as an enabler of greater efficiency. In addition, process automation and predictive maintenance are opening the door to smart factories and products, and both equipment suppliers and users need to develop new competencies in software rather than hardware. At the same time, packaging and processing machines are expected to be more flexible than they used to be. E-commerce, combined with broader and more complex product portfolios, creates the need for highly flexible systems that, ideally, customers can adapt themselves. Machinery suppliers need to develop modular solutions with greater standardization of system components to optimize their internal complexity and costs. Standardization is also a means for them to cope with the growing mid-price segment.

We offer consulting services across all STEP areas

The STEP trends are impacting the future development of the packaging and processing industry. Formulating clear strategies on how to respond to the changing market environment is the way to secure the success and sustainable growth of companies.

As an international consultancy, Roland Berger builds on a global network of experts across the end-to-end value chain, from raw materials and inputs to conversion to end markets and circular economy players which enables us to understand the issues from a wide industry perspective and cover local nuance.

We offer the right services to help our clients in the packaging, processing, equipment and packaging services industry achieve sustainable growth. In many projects, our consultants start with a 360° check to identify and analyze the current key factors impacting our client's business. In each STEP area, we provide unique support to our clients, ranging from the development of a sustainability strategy and roadmap to the optimization of operations, including procurement. In addition, we provide advisory services to investors. Our offerings include commercial, vendor and operational due diligence, acquisition target search and screening, and support during the M&A process.

Sign up for our newsletter and get regular updates on packaging and processing topics.

_person_144.png)