How the recycling of paper-based hybrid packaging can help packaging manufacturers to reach European sustainability targets and remain competitive

Chemical recycling via pyrolysis – Closing the loop in the plastics industry

An established technology becomes commercially viable

Over the past five years, EU consumers generated around 33 million tons of plastic waste, up roughly three percent year-on-year. Only 40 percent is recycled, the majority ending up as landfill or in incinerators. The result? Harmful CO2 emissions, polluted landscapes and widespread environmental damage. But a solution may already exist.

"Chemical recycling closes the loop for the plastics industry by re-converting plastic waste into its original components – potentially opening the door to a multibillion euro market."

The plastics waste issue is a growing global problem. But while recent recycling initiatives show promising results, there are limits on what conventional recycling can achieve. In particular, the recycled materials produced are often of lower quality than non-recycled materials and therefore of limited use. Post-consumer plastics are also often difficult to treat at reasonable expense. And a significant stream of mixed plastics waste exists for which conventional recycling is simply not an option.

Pyrolysis – an established technology finds a new application

However, a partial solution to the problem may already exist. Pyrolysis is a well-known technology that is already established in certain applications, such as the production of charcoal. Its use in the treatment of plastic waste is still relatively new, but several pilot plants around the globe have successfully demonstrated the concept. It is particularly suitable for treating mixed plastic waste, and the circular products it produces – be they naphtha, distillates or waxes – come without any compromise in terms of quality or suitability for end-use applications.

Understanding the market

Existing pyrolysis plants currently have a processing capacity of just 20,000 metric tons of plastic waste per year. But a number of market players have announced the construction of new facilities over the coming five years that will have capacities of more than 200 kilotons each.

As pyrolysis replaces landfill and incineration, we calculate the potential addressable market value of mixed plastic pyrolysis in 2022 to be around EUR 5.6 billion. This figure will remain largely stable over the coming decade, even with higher rates of mechanical recycling. Products with a circular end-use, such as naphtha to produce circular plastics and waxes, are in high demand and can achieve a premium in the market.

Competition is heating up

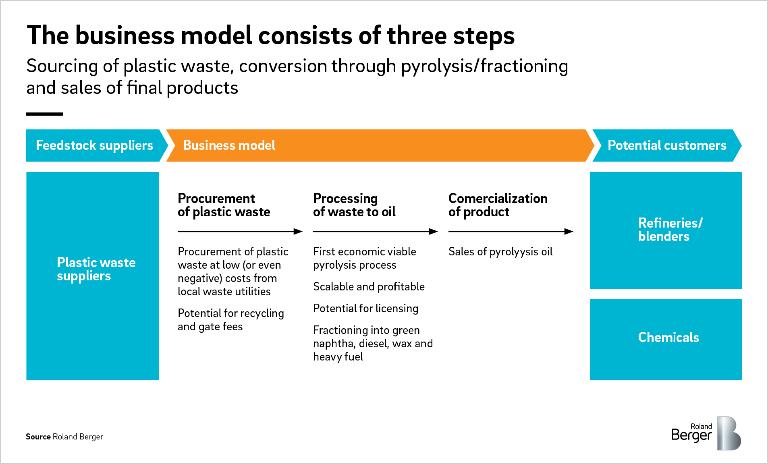

Sustainability considerations and a strong regulatory push will drive market growth going forward. At the same time, the number of players will increase. The current market consists of direct players (companies operating pyrolysis plants transforming plastic waste into pyrolysis oil) and indirect players (companies from the waste and recycling industry and players that produce pyrolysis oil from other feedstock). Several players have formed strategic partnerships with chemical or oil companies. While some hopefuls will certainly succeed in the market, others will likely fail to reach commercial viability.

What lies ahead?

For pyrolysis to realize its full potential as a circular solution , it needs a supportive legal framework. In particular, pyrolysis and other chemical recycling technologies should count towards recycling quotas under EU legislation. Market players also face the challenge of scaling up to commercial operations. Those with strong technological capabilities and a smart setup, with access to adequate volumes of mixed plastics waste, will have the greatest chance of success – and can help establish pyrolysis as a vital component in the transition into a circular world.

Register now to download the full publication on chemical recycling via pyrolysis and its future potential and get regular insights into energy & utilities topics.