The traditional view on circularity has focused mainly on lowering energy consumption and emissions. But these are only a part of the story.

_download_preview.png)

Circular economy solutions for industrial firms

By Christian Böhler and Hannah Zühlke

From reusing to refurbishing – a comprehensive approach

The circular economy, a compelling concept offering actionable alternatives to traditional recycling methods, emerges as businesses seek sustainable solutions for long-term growth. It holds promising potential to reshape industries and foster resilience in the face of environmental challenges.

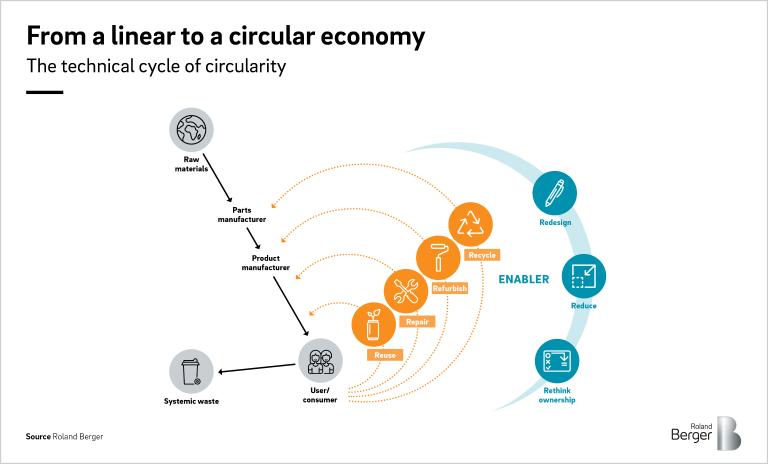

In a changing world of production, embracing the circular economy holds the promise of a profitable and sustainable future. As it stands, 91 percent of our economy is built on a linear basis, meaning products are made from new resources. When we switch our focus to a circular economy, the essence lies in preserving the value of resources, materials, and products, a concept manifested through the 4 Rs - reusing, repairing, refurbishing, and recycling. As industrial manufacturers explore this novel territory, they encounter a pivotal choice – striking a balance in optimizing manufacturing efficiency while applying the teachings from the technical cycle. Yet, the allure of this paradigm extends beyond the realm of environmental impact, promising enticing cost savings to those who can think far enough into the future. In addition, potential clients will see how adaptable the company is, and players could earn an enhanced appeal to the upcoming workforce. Moreover, such a strategic move aligns with the European Union's Green New Deal and future regulatory measures, cementing businesses' commitment to sustainability and propelling them towards a path of continued growth.

Decoding the essence of circularity

Circular manufacturing entails a comprehensive approach, involving every facet of a company. From designers and engineers looking to see how products can be used differently in the future, to supply chain management optimizing waste-to-resource management – each function has a role in embracing circularity.

Among the 4 Rs, reusing stands as the most impactful in reducing emissions. By extending a product’s lifespan through minor modifications or cleaning, the need for new materials diminishes. For example, automobile manufacturers can adopt closed-loop systems, remanufacturing and reusing certain components from returned vehicles. In this way, they minimize waste and conserve valuable resources.

Repairing takes center stage as the next crucial option. By restoring damaged products, businesses can minimize waste and offer cost-effective solutions to consumers. This approach is already prevalent in various business models. This is because technology companies offer repair services for their electronic devices, which extends the life of the products and reduces the demand for new purchases.

Parallel to repairing lies refurbishing, the third R in a circular economy. This process involves restoring or enhancing a product to a like-new condition through repairs, replacements, or upgrades, thereby extending its useful life and increasing its value. By carefully examining the entire product lifecycle, refurbishment opens the possibility of a second life for products after their initial use. For instance, researchers at RWTH Aachen University in Germany found that used car batteries with 70 to 80 percent remaining capacity could be repurposed for household-integrated energy storage, significantly prolonging their utility, and promoting sustainability in the industrial sector.

Recycling becomes the final measure to be considered after all other options have been exhausted. This essential step helps to close the loop on the lifecycle of products, preventing them from becoming waste while ensuring valuable materials are recovered and repurposed. An exemplification of this principle is the collection of sorted material waste, particularly aluminum scrap from presses, which is promptly returned to their suppliers to be recycled immediately. This closed-loop approach achieves two objectives: mitigating environmental impact and enhancing resource efficiency. Together, the 4 Rs give companies multiple touchpoints to evaluate their practices and how they can remain competitive.

"Embracing the circular economy is more than a shift - it's a revolution in innovation and collaboration, fostering new business models and value chains to harmonize economic advancement with environmental sustainability."

The circular economy in practice: Cutting-edge technologies

Innovation and technology play a pivotal role in realizing the full potential of the circular economy. Augmented reality (AR) emerges as a groundbreaking tool that revolutionizes how repairs are carried out. By seamlessly blending virtual elements with the real world, AR empowers users with step-by-step visual instructions, effectively eliminating the need for traditional manuals. This transformative aspect of AR not only enhances repair efficiency but also democratizes the repair process, making it more accessible to individuals with varying levels of technical expertise.

Additive manufacturing (3D printing), on the other hand, stands poised to possibly revolutionize production processes. Unlike traditional manufacturing methods that involve subtractive processes (cutting, drilling, etc.), 3D printing builds objects layer by layer from digital models. Various materials such as plastics, metals, ceramics, and even biomaterials are used. Traditional manufacturing often generates a substantial amount of waste as materials are cut and shaped to achieve the desired product. In contrast, 3D printing is an additive process, which means it only uses the exact amount of material needed to create the object. This reduces waste significantly.

Furthermore, from a business model point of view, a shift is challenging the traditional linear structure of product acquisition and disposal. Emerging business models like product-as-a-service and material-as-a-service are fundamentally reshaping the interaction between consumers and products, opening doors to an array of complementary services. By retaining ownership of assets and offering flexible usage options like leasing or pay-per-use agreements, companies are driving maximum utilization and encouraging eco-friendly practices.

Nevertheless, embracing the circular economy presents its share of challenges. A meticulous cost-benefit analysis brings to light that certain circular solutions might necessitate substantial upfront investment, possibly falling short of covering expenses under prevailing legislation. In fact, a majority of measures to increase sustainability in business and production models fall under the category of "high-effort/high-benefit," where the potential gains are substantial, but the investment of time and resources might be more significant. Some of these innovative processes could involve a lengthy break-even point, while others may never fully recover costs. To maximize the potential benefit of these options, companies should think further into the future while planning, in some instances, 3-5 years ahead, or even more. As the effects of climate change become more relevant, these adaptations are becoming more necessary as the incoming work force of Generation Z increases pressure along with increasing regulatory pressure.

Another point to consider is that it cannot be expected that all industrial environments apply the 4 Rs on a one-size-fits-all basis. The nuances of these strategies fluctuate not only between different industries but also within individual companies. What proves most effective in one case may entail a combination of two of the Rs while in another, pure recycling might be the optimal approach. This diversity of levers calls for tailored solutions, underscoring the need for a nuanced and adaptable approach to achieve sustainable practices across the industrial landscape.

To ensure that the circular economy is integrated into the industrial sector, decision-makers must diligently follow a comprehensive checklist of tasks. This includes clearly elucidating stakeholders' expectations, providing precise instructions to design engineers, ensuring utmost transparency in procurement practices, and discovering viable, reusable solutions.

"The circular economy is both: An enabler for sustainability (especially decarbonization) as well as an important lever for risk mitigation for a companies’ operations."

The current regulatory field

The regulatory field will encourage such practices in the future. In a determined push towards sustainability, the European Union's Green Deal charts an ambitious course for achieving net-zero emissions by 2050 and untangling economic growth from resource consumption. At the heart of this effort lies the second Circular Economy Action Plan, emphasizing legislative actions to foster circularity along product value chains. The EU sets sights on transforming its economic landscape. Measures to promote this include, strategic product design promoting durability, repairability, and recyclability, enhanced consumer empowerment, and circular practices in production and waste management.

Meanwhile, China advances its circular economy ambitions with a long-standing Circular Economy Promotion Law and a qualitative vision for improved waste recycling and energy efficiency. In the United States, the Environmental Protection Agency leads recycling endeavors through the National Recycling Strategy, while certain states enact producer responsibility laws to curtail single-use plastic packaging. As the global drive for circularity intensifies, these measures reflect a more united front in sustainable management.

By incorporating the principles of circular economy management and the 4 Rs, industrial manufacturing companies can position themselves at the forefront of modeling a new terrain. As innovation and regulation converge, the circular economy presents a compelling opportunity to create a positive impact on our planet while securing long-term stability for businesses and communities alike.

In our latest study, “What goes around, comes around – The circular economy in industrial manufacturing,” you can find the newest research results and expert assessments on the opportunities and risks for international market players. In addition, the study covers the development potential of the circular economy in the upcoming years. Below you can download the insightful and comprehensive report.

Register now to download the full study with key findings, new developments and our recommendations for a smooth transition from a linear to a circular economy.