Climate protection in the manufacturing sector: Challenges and solutions

Businesses need strategies to switch to low-carbon or carbon-neutral production processes

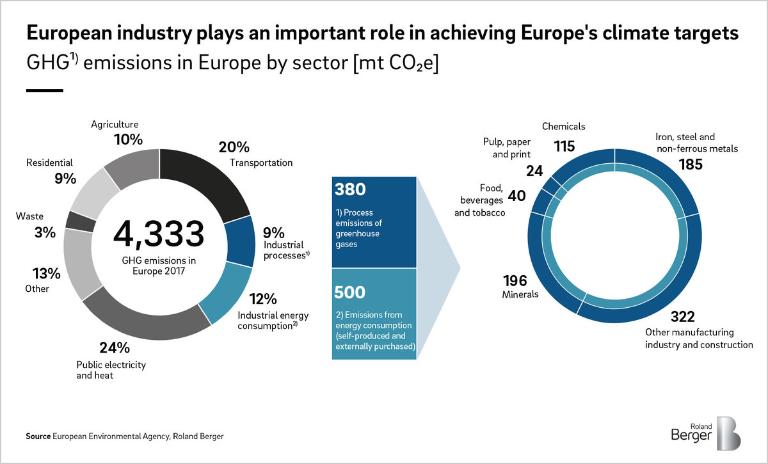

Immense efforts will be needed to achieve Europe's climate targets for 2050. The manufacturing sector bears a particular responsibility here, emitting an annual total of 880 million tons of carbon dioxide equivalents (CO2e, referred to for simplicity as CO2 or carbon emissions here). This makes it one of the largest single emitters of greenhouse gases in Europe. Industry therefore has a duty to address the issue of greenhouse gas reduction, especially as legal regulations are expected to tighten and public pressure will only increase. As companies transform their business toward carbon neutrality, it's important to act fast to exploit the opportunities that arise.

The European Parliament has declared a "climate and environmental emergency" for Europe. The new President of the EU Commission, Ursula von der Leyen, plans to make the EU-wide fight against climate change her absolute priority and sees the bloc acting as a global role model with its efforts in this regard. The tightening of EU carbon emissions trading and supplementary climate protection regulations for the member states will therefore likely lead to significantly stricter requirements and heavier financial burdens on key greenhouse gas emitters in Europe. Given the industrial sector's high CO2 emissions, it is especially important for manufacturing companies to consider ways of reducing their carbon emissions in the coming years.

However, the EU is not just interested in imposing additional taxes on greenhouse gas emitters. It is also making large sums of money available to subsidize new, climate-friendly technologies and production processes that businesses can turn to their advantage. In addition, early studies suggest that companies' efforts to protect the climate are very well received by their own workforce. Decisions made by the capital market and end consumers themselves also give increasing heed to companies' environmental performance these days. A major globally operating British bank, for example, analyses its customers' carbon footprint alongside the classic KPIs prior to granting loans and then offers them on more attractive terms to companies that meet certain sustainability criteria. Since 2015, an insurance group that is also active worldwide has even completely pulled out of insuring and financing coal-based (and thus highly carbon-intensive) business models.

In view of the importance of climate protection for society and the fact that the manufacturing sector is responsible for a large proportion of Europe's greenhouse gas emissions, many companies are striving to reduce their carbon emissions and have set themselves specific targets in their Corporate Social Responsibility guidelines. Most large corporations are already actively communicating their ambitions in this way, with many even citing specific dates by which they plan to be completely carbon neutral. Some of the key ways in which industry can play its part in achieving climate targets are by consistently using renewable energies, by increasing energy efficiency levels and by adapting new production processes.

The GHG Protocol Corporate Accounting and Reporting Standard provides guidelines and advice for businesses on identifying their greenhouse gas emissions across the whole company. It incorporates the seven greenhouse gases cited in the Kyoto Protocol.

Transparency over a company's carbon footprint provides a basis for decisions

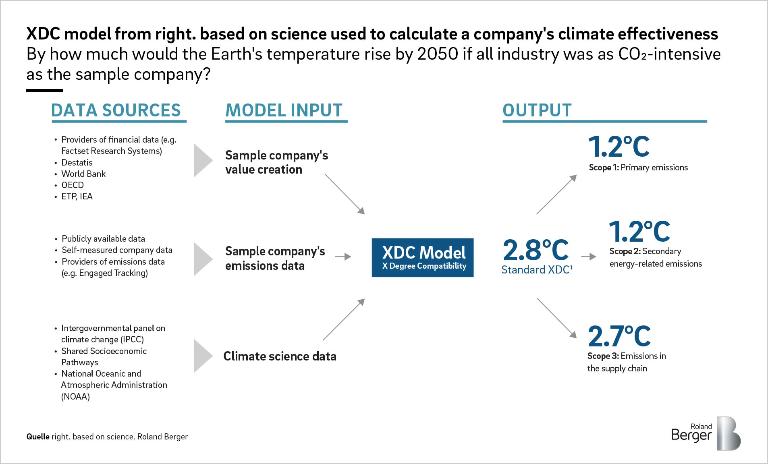

A transparent system for systematically controlling the amount of greenhouse gases emitted by businesses is needed to reliably measure the impact of the actions they take and make the findings available to the public. To calculate their carbon footprint, companies already have the first international standards at their disposal, such as the GHG Protocol Corporate Accounting and Reporting Standard. However, there are still no central testing bodies, and consequently it is not possible to reliably compare either the current emissions data or the impact of climate protection initiatives planned by individual companies.

A number of startups, NGOs and government organizations have set themselves the goal of creating transparency here in a bid to support decision-making by shareholders, customers, investors and political actors. The startup "right. based on science" with its XDC model (XDC = X-Degree Compatibility; see infographic) is pursuing a promising approach in this regard. The model makes it possible to calculate – individually, for each company – how much the global temperature level would rise under certain scenarios if the entire industry were as carbon-intensive as the company in question. On this basis, companies can determine their own need to take action to reduce their greenhouse gas emissions and can compare themselves against their relevant peer group. In addition, businesses can determine the climate effects of any planned CO2 reduction measures and run scenario analyses.

Need for investment and action to reduce greenhouse gas emissions varies greatly between industrial sectors

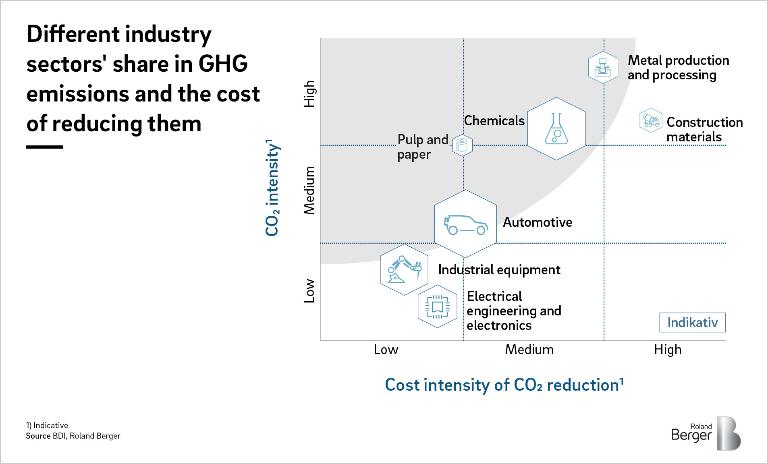

There is no doubt that society at large and industry itself are going to have to make enormous efforts to reach Europe's ambitious goal of achieving carbon neutrality by 2050. The amount of investment and effort that an individual company will have to make varies considerably depending on the type of production processes it applies and their respective energy intensity (see infographic).

High emissions and significant costs of reduction in the metal, chemical and construction materials industries

A disproportionately high share of industrial greenhouse gas emissions comes from the metal, basic chemicals and construction materials sectors. The challenge for companies in these industries is therefore particularly great. Their high CO2 emissions are partly due to the energy intensity of the production processes they use. But greenhouse gases are also produced in the production processes themselves, for example as a byproduct of the blast furnace converter process commonly used in steel production or during the burning of cement clinker and lime production in the construction materials industry.

However, the development of CO2-optimized production processes is progressing. Various companies have already taken such processes to a high level of technical maturity and intend to push ahead with pilot projects over the coming years. Several large steel groups, for example, are developing parallel processes for CO2-reduced steel production.

Three ways to reduce CO2 emissions in the steel industry

-

- Using hydrogen instead of coal dust as reducing agent in the blast furnace process > CO2 savings potential: approx. 20%

- Converting from the blast furnace method to direct reduction. This produces so-called sponge iron, which can be processed into crude steel in electric arc furnaces > CO2 savings potential: approx. 20-30%

- Carbon capture and utilization (CCU): Capturing the blast furnace gases produced during steel manufacturing and using them as a raw material in the production of basic chemicals > Total elimination of CO2 emissions possible

The chemical industry is also embarking on efforts to reduce its process-related CO2 emissions. Examples include the use of hydrogen from renewable sources, which enables emission-free ammonia synthesis. However, the cost of investing in the new production processes is high, and this, combined with long payback periods on the necessary plant and equipment, stands in the way of rapid and comprehensive conversion in Europe. In addition to the considerable investments required, the high demand for green electricity and renewable hydrogen presents a further barrier to the use of carbon-neutral or low-carbon processes in the steel and chemical industries. Although the European Commission is vehemently pursuing projects to promote renewable energy production , there will not be enough green electricity in the foreseeable future to meet the high demand for renewable energy that comes from low-carbon production processes.

Reducing energy-related greenhouse gas emissions through the use of renewable energies

Most manufacturing companies outside the steel, chemical and construction materials industries emit CO2 primarily through their energy consumption, which they may use for the purposes of process heating or cooling, mechanical energy, room heating or lighting, for example. To reduce these energy-related emissions, manufacturing companies can address two main levers. First, they should minimize their energy consumption by consistently using energy-efficient technologies. Second, they should meet their remaining energy demand from renewable sources as far as possible and should also, where appropriate, use their own decentralized power generation capacities.

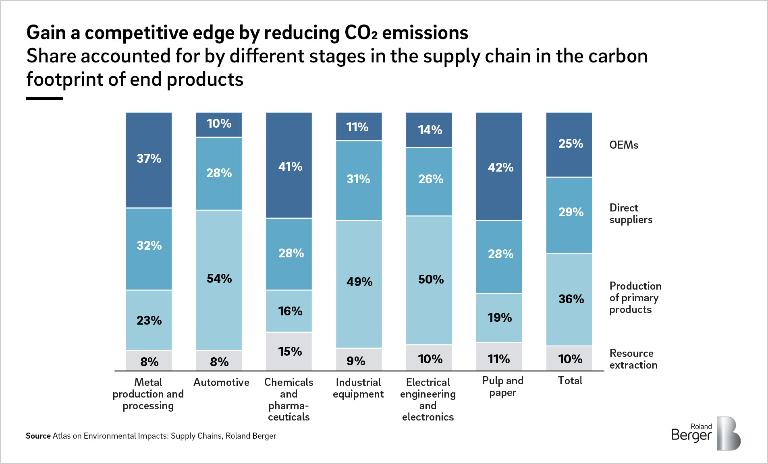

The supply chain presents another significant lever, as we can see by looking at the carbon footprint of end products (see infographic). On average across all industries, only about one quarter of a product's total greenhouse gas emissions comes from the OEMs themselves. The rest is created in the supply chain during transportation and in upstream production processes at supplier companies. OEMs are therefore heavily reliant on their suppliers and subcontractors when it comes to calculating and reducing the total carbon footprint of their products. Some suppliers have already recognized this as an opportunity and are giving themselves a competitive edge by proactively supporting their customers in their efforts to reduce carbon emissions.

Conclusion: Climate-friendly production requires a clear roadmap and cooperation along the entire supply chain

In view of the global climate protection movement, manufacturing companies will not be able to avoid developing their own CO2 reduction strategy in the near future. Such a strategy will need to serve as a basis for their long-term switch to low-carbon or carbon-neutral production and must take various dimensions into account. It must also include a range of potential scenarios to reflect the different political and social developments that may occur.

In order to be effective and targeted, a company's corporate strategy for CO2 reduction must be optimally aligned with the production processes it employs and the product portfolio it offers. At the same time, the necessary changes in production must not place an overly large burden on the company's financial resources, and the business must retain its ability to compete in the international arena. A key component of any targeted CO2 reduction strategy is a long-term implementation plan with specific measures scheduled to be taken at specific times. Since a large part of any product's carbon footprint is created in the supply chain, close coordination with suppliers must also be planned throughout the entire process.

On the political side, prudent action is necessary to support manufacturing companies in implementing their CO2 reduction strategies and to avoid placing firms at a competitive disadvantage as a result of legal requirements. The continued, consistent promotion of renewable energies and power grid expansion as well as the subsidization of investments in CO2 reduction are important enabling factors for the transformation. Additional regulations, such as increasing the cost of industrial CO2 emissions through continuous expansion and price increases in the EU emissions trading system, are important levers for engineering rapid and timely change. However, it is essential that Europe's manufacturing companies are not disadvantaged against other international players and that CO2 saved in Europe is not simply emitted elsewhere by relocating production to other regions of the world. The levying of carbon tariffs to increase the price of products from countries that do not apply carbon pricing could effectively avoid this problem.