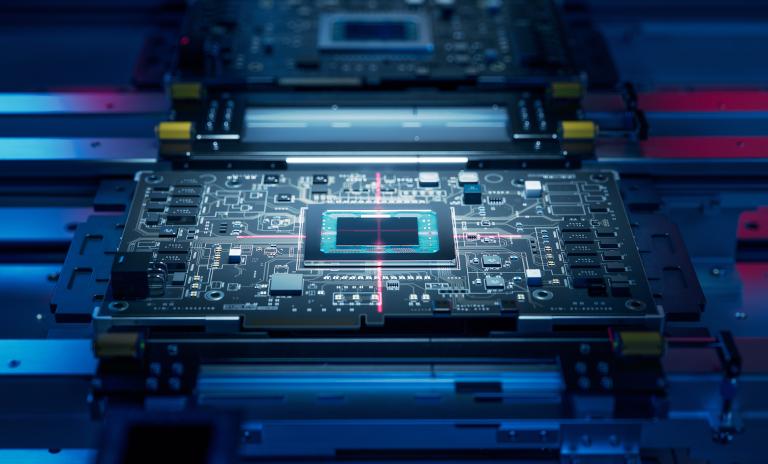

Electronics manufacturers finally register significant improvements in profit margins, but uncertainty remains prevalent. Maintaining this profit increase while simultaneously growing revenue will prove challenging. Due to this issue, Roland Berger carried out an in-depth market analysis which highlighted five main priorities for leaders in the electronics manufacturing services (EMS) sector.

Deglobalization in EMS – An industry on the move

As EMS providers weigh up reshoring in response to trade tensions and supply chain worries, Roland Berger reveals attractive alternatives to existing footprints

Despite huge advances in automation, the important role of human labor keeps manufacturing wages at the forefront of EMS providers’ deliberations on where to base themselves. For a good three decades, China has mostly been the go-to answer.

Lately, however, growing protectionist tendencies have combined with supply chain disruptions, unpredictable shipping costs and geopolitical concerns to call this status quo into question. While manufacturing wages naturally remain important, companies are now also searching for local/regional solutions that are business-friendly, politically stable and already possess the relevant infrastructure and ecosystem. The question is: Which countries or regions fit the bill?

Alternatives to China?

In light of these considerations, Roland Berger examined what 48 countries have to offer EMS companies that may be looking at reshoring their activities. Its assessment focused on three key benefits: competitive manufacturing wages, a functioning electronics ecosystem on the ground and ease of doing business in a stable political climate. Taken together, these vital factors open up attractive options for firms in the EMS space to build resilient local-for-local production footprints in order to deglobalize and de-risk production and supply chains.

"A careful balance must be struck between maintaining an appropriate local presence and optimizing EMS providers’ global capacity."

Roland Berger’s in-depth analysis singles out a total of nine countries, each well placed to support EMS production and supply operations in three regions: Asia Pacific, the Americas and the EMEA. The countries identified each offer a unique combination of attractive labor costs, established infrastructures and stability. Some names on the list, such as Mexico with its excellent manufacturing hubs, will come as no surprise. Others, such as Indonesia, have long flown under the radar but are now emerging as genuinely viable and competitive options.

China is not finished yet!

As important as local strategies undoubtedly are for robust and resilient EMS production and supply chain setups, the new study also stresses the importance of finding tailored solutions. Local content rules alone ensure that China – like India – will remain a necessary component of every company’s production configuration going forward. For most, striking a healthy balance will be the watchword. Looking at individual issues such as specific skill sets and genuine local demand, the Roland Berger assessment therefore concludes with five practical recommendations for every EMS company to get started on reviewing its existing manufacturing footprint.

Access Roland Berger’s full assessment and learn how your company can begin its own individual reshoring journey well equipped for success. Alternatively, we would welcome the opportunity to talk to you in detail about fleshing out a tailored deglobalization strategy that meets your needs and those of your customers.

Register now to access the full study, to learn more about attractive alternatives to existing footprints in the Electronics Manufacturing Services industry and about factors that play an important role when it comes to choosing a country or region.