The pressure die casting (HPDC) process, in which molten metal is injected into a mould under high pressure, is commonly used in the automotive industry to produce small to medium sized aluminum castings. Now, however, companies such as Tesla have extended its use to the production of larger car parts with complex designs up to 1500 mm, and other car manufacturers are wondering whether they should follow suit.

How megacastings are reshaping the automotive industry

Momentum and impact on the auto value chain

Megacasting – the production of large-format high-pressure die-casting (HPDC) parts – is radically simplifying automotive production. While the automotive industry first widely accepted HPDC in the 1980s, it was not until 2018 that the first megacasting presses with a clamping force of more than 6,000 tons were introduced. 2020 saw the first series production of a vehicle with a megacast rear end, since then there has been rapid uptake of the production technology by original equipment manufacturers (OEMs) and now Tier 1 suppliers. But while Chinese automakers are pushing megacastings aggressively, Western players have been somewhat more hesitant. We look at the challenges facing legacy players and the impact across the automotive value chain.

"Adapting to megacastings will be key for automotive Tier 1 and OEMs. Collaboration will be crucial."

Why megacastings?

A number of factors are currently driving adoption of the new technology. Electric vehicles (EVs) require the creation of new platforms with completely new designs that rely on megacastings. The vehicle bodies for EVs also have to be light, for which megacast parts are ideal. In addition, megacastings reduce both costs and complexity for manufacturers. EVs further lack legacy manufacturing capacities and architectures, giving positive momentum to growth of the new technology. Not only that, technological advancements now allow for larger component production with presses with more than 12,000 tons clamping force and suitable alloys. However, a number of challenges remain. Apart from the high cost of developing new megacasting lines – a burden on incumbent players' cashflow in already economically tense times – scrap rates are still high, in some cases as much as 50%. Efficient crash repair processes are needed, as megacast components are difficult to repair, creating difficulties for workshops and insurance companies alike. And the cost of die adaptations remains significantly high.

Global disparity

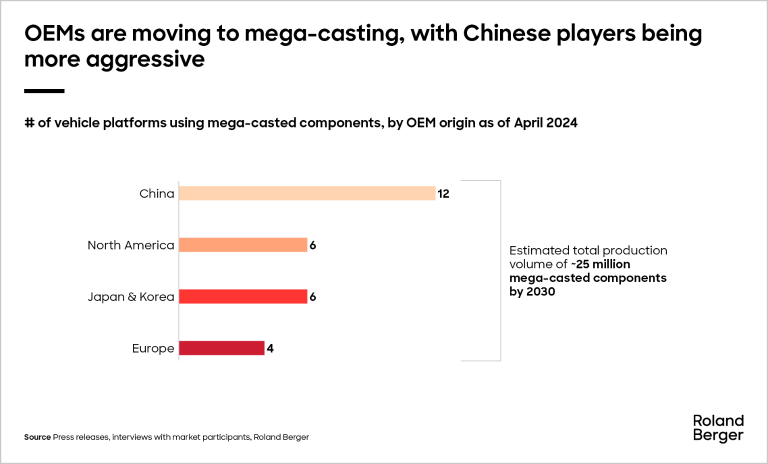

An examination of the global industry reveals that Chinese automotive players are currently pushing the new technology more aggressively than their counterparts elsewhere. Globally, more than 180 presses have been ordered to date, and Roland Berger foresees estimated total production of around 25 million megacast components by 2030. As of April 2024, China has 12 vehicle platforms using such components, while there are six in North America, six in Japan and Korea, and just four in total across Europe.

What lies behind this regional disparity? The key factor appears to be the existence of legacy production plants and machinery. North American and European players, for example, have invested heavily in building up production facilities and are hesitant to shift to the new technology for cost reasons. New market entrants, by contrast, operate on greenfield sites and can use the new technology from the outset, potentially giving them a sizeable advantage over established players.

"Megacastings are reshaping the value chain, from the production of raw materials to the shape of the aftermarket."

Reshaping the value chain

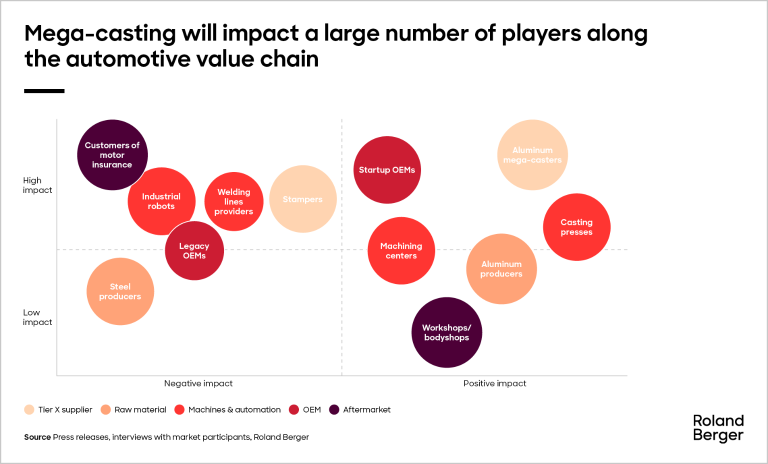

The widespread adoption of megacastings will lead to significant changes in the value chain – from the production of raw materials to the aftermarket. For those adopting the technology, a significant part of the assembling and welding processes is simplified, one megacast component potentially replacing as many as 100 welded parts. The pressure is particularly strong on stampers and the providers of welding lines and industrial robots. Legacy OEMs will also face challenges in capital expenditure (CAPEX) as they transform their production lines, and steel producers will see demand fall in favor of aluminum. In addition, motor insurance costs are likely to go up for consumers as a broken or deformed megacast component – for example, a rear-end module – often requires costly full replacement.

But, as in all situations of change, there will also be winners. The growing demand for megacast parts is obviously good news for suppliers with aluminum megacasting capabilities, and increasing demand for tooling will benefit casting press specialists. Startup OEMs will be at a distinct advantage over incumbents, as discussed above. Machining centers, aluminum producers and workshops will also see some degree of positive impact on their business.

Depending on their positioning along the value chain and disruption by Megacastings, companies must take action to limit risk or leverage exposure:

- Industrial robot and welding line providers shall suffer from simplification of operations and decreasing number of lines

- Legacy OEMs might suffer from legacy assets and architecture not competitive enough to fight against startup OEMs / newcomers

- Stampers and steel producers would likely see decreasing dynamics at the benefits of aluminum suppliers, megacasters and their partners – machining centers to cater for higher finishing requirements from Megacastings and press / tooling manufacturers

- Increasing complexity of repair will benefit workshops / bodyshops but higher costs of repair should drive up motor insurance premium for customers

The road ahead

Our advice for the industry? Players must take action to address the changes occurring in the industry, and they should do so sooner rather than later. Megacastings are already a reality in a number of series production platforms, and they will become even more widespread as new platforms and designs reach the market in 2030-35 – including those of legacy automakers. Companies that fail to react now will find it difficult to make the necessary adaptations later on. Now is the time to ride the momentum for change.

Sign up for our newsletter and get regular updates on Automotive topics.

_person_144.png)

_person_320.png)