Explore the future of European rail in 2024: sustainability, reliability, and connectivity. Uncover the blueprint for operational excellence and a greener tomorrow.

Navigating sustainability challenges in rail

Upstream decarbonization can solidify rail as the most environmentally-friendly way to travel

Train travel is the most sustainable form of long-distance transportation, and governments around the world focus on expanding the (inter)national rail networks. However, for rail companies sustainability is evolving from being their key strenght into a pivotal improvement lever for the successful execution of rail business. Governments worldwide are exerting increased pressure on companies to demonstrate social and environmental responsibility and progress towards a more positive impact. Recognizing the transformative power of sustainability, Roland Berger emphasizes the need for a paradigm shift in evaluating rail operations. Decarbonization of rail is more than just electrifying trains; it requires comprehensive action across the value chain to reduce scope 1, 2 and 3 emissions. Roland Berger recognizes the challenges faced in rail, and supports companies to achieve sustainability requirements. At its core, decarbonization is an opportunity for companies and the sector as a whole to preserve and enhance rail as the most environmentally-friendly form of travel.

Decarbonization in rail spurred by evolving regulatory requirements

Historically, the focus of sustainability in rail operations centered on environmental protection, energy efficiency and procuring zero-emissions electricity. However, evolving regulatory requirements push the industry to broaden its perspective. Key topics along the rail value chain include holistic decarbonization strategies and circular economy principles. The impetus for decarbonization is driven by global accords like the Paris Agreement, necessitating a substantial reduction in scope 1, 2 and 3 greenhouse gas (GHG) emissions across all industries. Compared with other forms of long-distance passenger and freight transportation, trains, and especially electric trains, have lowest CO2e emissions per km. Increasing modal shift from air or road to rail for passenger as well as freight transport is key in reducing GHG emissions from the transportation industry. At the same time, all rail companies will need to set targets and act on these to further reduce absolute emissions from rail.

From their peak in 2019, direct CO2e emissions from rail remain under 100 Mt CO2e globally, though absolute emissions have been increasing since the absolute lowest point during COVID-19 year of 2020. To get on track with the Net Zero Emissions by 2050 (NZE) Scenario from the International Energy Agency (IEA), emissions from rail will need to decline by about 5% annually to 2030.

The required 33% reduction in direct CO2 emissions (scope 1) is already a serious challenge, let alone reducing scope 2 and 3. Scope 1 and 2 GHG emissions are within direct company control, and are prioritized for short-term reduction plans, while scope 3 emissions often pose greater and unique challenges. Within scope 1 decarbonizing trains, stations and other buildings are the prominent concerns. Reducing scope 2 emissions is related to implementing efficiency measures to reduce energy consumption and purchasing zero-emission energy. Reduction of scope 3 emissions is about measuring and reducing emissions across the value chain. Based on a selection of rail companies that report in detail on their emissions, scope 3 presents the majority of GHG emissions. Scope 3 includes mostly emissions from suppliers of goods and services.

Rail companies still mainly focus on short-term targets

Emission targets

Beyond measuring greenhouse gas emissions, it is key to set reduction targets. Multiple rail companies have committed to the Science Based Targets initiative (SBTi), which is an initiative that validates organization’s targets in line with the Paris accord and the best-known standard for target setting. A well-rounded decarbonization strategy should encompass both short and long-term goals, but many rail companies have no comprehensive reduction targets (yet).

When it comes to the scope 1 and 2 carbon reduction ambitions of these companies, we find that many companies either do not yet have any net-zero targets, or mainly have short-term objectives. The majority fall short in setting comprehensive, long-term targets. However, Dutch Railways (NS), Ferrovie dello Stato (FS), and Danish State Railways (DSB) do have ambitious long-term targets, all of which are approved by the SBTi.

The overview in figure 4 only shows the level of SBTi targets set by the rail companies for their Scope 1 and 2 emissions, and does not show current emission levels. Most companies also set targets for Scope 3 emissions, though often less ambitious or based on intensity of emissions, which is less comparable.

Decarbonizing train operations

To meet ambitious decarbonization goals, a systemic approach to train operations is imperative, and procurement of energy, trains, raw materials and services a.o. is one of the key elements. The available options to reduce emissions from train operations highly depend on the current situation. If trains are already electrified, rail operators should look into increasing energy efficiency and reducing emissions from purchased energy, by switching to zero- or low-emission electricity. The energy use pattern must be taken into account when looking for the best-matching energy source, further complicating procurement. From our support with securing substantial renewable energy PPAs (Power Purchase Agreements) for large energy users, including rail operators, we have learned that electricity production from solar and wind is not in line with electricity demand for trains. Therefore, a mix of zero-/low-carbon energy sources as well as energy storage solutions must be taken into account.

Though all trains running on zero-emission electricity using overhead catenary or third rail may seem like the ultimate goal, costs and (scope 3) emissions from construction of trains and electricity infrastructure cannot be ignored, and therefore other options may need to be explored. For certain routes or specific regions, it may be more sustainable to switch from diesel (with high CO2e emissions) to alternative fuels, such as low-emission biodiesel. Pure biodiesel can result in a GHG emission reduction of up to 90%, while train technology does not need to be updated and fuel costs are only marginally higher. Production and therefore procurement of sufficient biodiesel is currently a challenge, but acceleration is pushed by several marine and road fleet operators. Other options such as (green) methanol and hydrogen have not yet reached, and might never reach, the sufficient maturity and cost-efficiency stage to be implemented at scale. Hydrogen fuel cells are attracting significant interest, and test trains have been running, as operation is possible over long non-electrified routes, and refueling is fast. Hydrogen storage on board is still a challenge, and hydrogen production is very expensive and inefficient resulting in significant CO2e emissions from non-renewable electricity production. Battery electric trains are another reasonable option to assess, with increasing efficiencies and quickly reducing costs. The weight of batteries will continue to limit the range of the vehicles, and emissions from battery production need to be taken into account, but railroad electrification combined with batteries for hard-to-electrify parts of the network is a serious option to consider.

Station and tracks decarbonization

Besides the trains, it is also necessary to decarbonize the tracks, stations and other buildings. But how do we do that without disrupting operations? Roland Berger has experience with taking a systematic approach to decarbonization. Sustainability efforts should, whenever possible, align with existing renovation plans and projects to minimize (additional) operational disruptions, though mandatory measures for compliance with laws and regulations should be prioritized. The project approach as depicted in figure 3 is aimed to optimize the tracks and stations’ sustainability and operability. Depending on the current situation, the project approach and focus areas would need to be adapted. While stations generally have significant Scope 2 emissions from purchased energy with room for improvement, emission reduction measures for tracks are more focused on Scope 3 emissions from construction and maintenance.

The journey toward sustainability involves not just reducing emissions but reimagining the lifecycle of resources. Rather than discarding materials, a circular approach encourages maintenance through repairing, recycling, refurbishing, remanufacturing or repurposing. This requires a reevaluation of product engineering, incorporating more recycled or biobased materials. Roland Berger has extensive experience with sourcing and accounting for green steel and concrete, which are two key components of buildings and rail tracks. We believe that, as (semi-)public organizations, rail companies should lead the way in more sustainable procurement strategies.

Taking a closer look at steel, it is one of the world’s most important construction materials, produced by one of the most CO2e -intensive industries. The steel industry in Europe currently produces ~6% of total EU CO2e emissions. Options to reduce emissions and improve circularity are growing though. Steel manufacturers are focusing on two main technologies to transition to CO2e -reduced steel, or so-called green steel: Carbon Capture, Utilization and Storage (CCUS) and direct reduction technologies based on natural gas or hydrogen. CCUS encompasses methods and technologies to capture CO2e during the production process, followed by recycling or permanently storing the CO2e. This can deliver up to 80% CO2e -emission reduction. Direct Reduction or DRI refers to solid-state processes that reduce iron ore into iron by a reducing gas or elemental carbon. The direct reduction process based on green hydrogen has the potential to deliver up to 99% CO2e -emission reduction, though sufficient green hydrogen production at a reasonable cost is still a challenge for the coming years. Green steel is expected to become gradually available from 2030 onwards. Another option is using recycled scrap, possibly mixed with virgin material, to produce new rails. Steel from recycled scrap has ~90% lower CO2e footprint than virgin steel, and steel producers are experimenting with increasing the share of recycled material in rail. Procurement departments of rail companies should approach steel suppliers to accelerate low-carbon technologies and increase scrap content. Roland Berger also strongly advises rail companies to consider teaming up with other rail companies in this effort.

Scope 3 emissions only reduced by fostering sustainable supplier partnerships

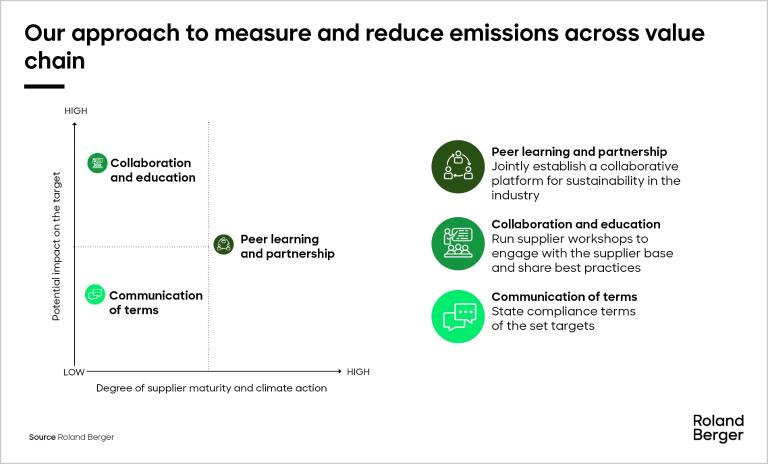

In addressing the intricate challenges in mitigating scope 3 emissions, effective collaboration with suppliers becomes paramount. Our approach is multifaceted, with an emphasis on partnerships. We suggest tailoring the intensity of collaboration to the suppliers’ potential impact and their degree of maturity.

Given the diversity of suppliers, three distinct forms of collaboration are pursued:

A. Peer learning and partnership: A collaborative platform is jointly established to foster sustainability within the industry. This platform serves as a hub for the valuable exchange of insights between suppliers and companies involved in carbon credit offerings.

B. Collaboration and education: Supplier engagement is facilitated through dedicated workshops, creating a space for interactive learning and best-practice exchange. These sessions contribute to a collective effort in understanding and addressing scope 3 emissions, aligning with the set targets.

C. Communication of terms: Recognizing the varied impact and maturity levels of suppliers, compliance terms for the established targets are clearly communicated. This method ensures a transparent framework for all stakeholders, driving accountability and adherence to emissions reduction goals.

Conclusion: Rail decarbonization is not only a must – it is an opportunity

The rail industry's trajectory toward sustainability is not merely a response to regulatory pressure; it represents a fundamental shift in business dynamics. Roland Berger's sustainability in operations approach positions rail enterprises at the forefront of this transformative journey. By developing a comprehensive climate action plan, rail companies can meet regulatory requirements while also unlocking new business prospects, ensuring a resilient and sustainable future for rail. To preserve and enhance rail as the most environmentally-friendly form of travel, especially as financial resources are limited, it is crucial to adopt a rigorous approach.

_person_144.png?v=798485)