Browse online articles from issue of Think:Act Magazine "Performance: Faster, Higher, Stronger"

Partnerships for improved performance

As hard times prevail, unexpected benefits can be reaped from carefully crafted collaborations

by Caroline Evans

Illustrations by Joe Waldron

The automotive sector has experienced many bumps in the road in recent years, but most have only impacted the profit margins of Tier 1 suppliers – and original equipment manufacturers (OEMs) have been reluctant to interrupt their own smooth journey to tow them to safety. However, shifts towards electric vehicle (EV) production, autonomous driving and sustainable business will encourage OEMs to cooperate more intensively with their suppliers. Sharing the burden of simultaneous challenges will soon be the only way to ensure successful performance for many industries.

"Despite a reduction in production volumes due to supply chain interruptions, the value per vehicle was unprecedentedly high in recent years, generating a boom."

Grim outlook for 2030

Several crises have impacted performance and profits in multiple industries in recent years. The Covid-19 pandemic, Russia’s invasion of Ukraine and high inflation have all generated challenges in supply chains for raw materials and equipment. Combined with new government directives in many countries to commit to net zero emissions, industries must rethink their approach to business success. In the automotive sector the relationship between original equipment manufacturers (OEMs) and their suppliers has become increasingly strained in the past couple of years. Both parties must contribute to a shift from conflict to collaboration soon to recover profit margins for the long term.

Tier 1 automotive suppliers – those supplying to OEMs directly – have faced numerous financial burdens recently, including higher price models for parts and materials. As a result, they are seeing dramatic dips in their profit margins. OEMs on the other hand have seen impressive figures. Sebastian Gundermann, senior partner, automotive, at Roland Berger, says, “Despite a reduction in production volumes due to supply chain interruptions, the value per vehicle was unprecedentedly high in recent years, generating a boom.” Manufacturers like BMW, VW, Toyota, GM and Tesla all reported record profits in 2022 from the years prior as consumers were willing to splash out on high-margin vehicles at even higher prices.

Nowadays, the outlook is quite different even for OEMs with real risks to stability and profitability in 2030 and beyond. Diverse, often interconnected, factors are the driving forces behind this.

Electrification

There is a growing shift in production from vehicles with internal combustion engines (ICE) to alternative, climate-friendlier electrified drive trains. UN proposals for a complete phase-out of GHG emissions by 2050 will eventually force all OEMs to switch to solely EV production – and possibly within the next decade. Any government-imposed halts in sales of new ICE vehicles, where a significant portion of cashflow and profits are usually generated, will have a drastic impact on OEM profit margins.

Battle for batteries

The rapid expansion of EV production globally means a steep rise in demand specifically for EV batteries. At least for now, as lithium-ion battery manufacturing is dominated by just a few key players, such as CATL and BYD in China and LG Energy Solution in Korea, OEMs are forced to pay whatever prices these companies demand for their end products.

Supply-chain challenges

Recent trade wars, the invasion of Ukraine and subsequent reduced production and logistics of vehicle parts, due to high oil and gas prices, have created supply-chain bottlenecks for most industries. To manufacture EVs, there is a heavy reliance on commodities such as rare earth metals for battery production which can only be sourced from Asia. The dearth of these raw materials continues to elevate prices for Tier 1 suppliers, but their dependence on procurement from limited markets means there is little room for negotiation. Therefore, OEMs considering production of their own batteries could be deterred by extortionate resource costs.

Digitalization

To stay competitive, OEMs must produce vehicles with autonomous driving capabilities, or at least provide more sophisticated software features for driver assistance. Such camera-based software is not in the realm of most traditional OEMs’ expertise, obliging them to outsource this to digital service providers at a high cost. Failing to invest would mean a potential risk to profits of around 10% as they fall behind even newer, AI-savvy companies producing vehicles with appealing digital features to be sold over online platforms.

Rising inflation

European and North American markets in particular have enjoyed stable low inflation for around 50 years. In recent months, these figures have skyrocketed to unexpected levels. The ongoing conflict in Ukraine has pushed rates – and therefore costs of most goods and services – even higher.

Deglobalization

Global trade has grown at a much slower pace for over a decade, but in the past few years global value chains have come under increased pressure. In response, despite the higher costs of doing so, companies have already relocated or are considering relocation of production premises to more local facilities.

Sustainability

OEMs must demonstrate their contribution to a circular economy with a commitment to producing emission-free vehicles, eliminating long-life hazardous materials from production lines and using sustainable resources which can be reused, recycled or remanufactured. Incentives in future could include subsidies for sustainable practices, whereas non-compliant OEMs may face high fees. They must therefore work closely with suppliers to find solutions, such as sourcing recyclable materials or salvaging and repurposing components from used EV batteries.

"The long-term contracts between Tier 1 suppliers and their OEM clients make them the only player in the value chain who cannot be relieved of rising expenses."

EVs sending insecure currents through the industry

Return on vehicle sales is likely to drop sharply for established OEMs beginning to produce a higher ratio of EVs than highly profitable ICE vehicles. The costs for EV parts are already comparatively much higher than those for internal combustion engines. Price models are likely to rise even further as companies compete to meet consumer demand and strive to manage a more sustainable business. Therefore, even OEMs already producing high volumes of EVs will see their profit margins fall. To stay competitive in a buzzing EV market, however, OEMs must also maintain affordable prices for consumers, again impacting their margins significantly.

Further suffering for suppliers

Tier 1 suppliers are facing additional financial pressures. Felix Mogge, senior partner, automotive, at Roland Berger explains, “The long-term contracts between Tier 1 suppliers and their OEM clients make them the only player in the value chain who cannot be relieved of rising expenses.” Costs of fueling ocean freight logistics have leapt over the past two years. Continual jumps in inflation have seen raw material suppliers demand even higher prices for their goods. Then the cost-of-living crisis for the everyday citizen drove workforces to join industrial action and demand salary increases. Tier 1 suppliers raising employee wages are thus burdened with even further costs which cannot be recouped.

Another factor is insecure demand for their stocks of materials and parts. Agreed production volumes frequently shrink to the minimum levels or OEMs postpone delivery if their manufacturing timelines change, all while offering very little compensation. The longer vehicle parts lay idle in warehouses, the greater the loss for Tier 1 suppliers. They are therefore trapped in a value chain which is highly beneficial to OEMs but detrimental to their own profit margins.

Collaboration driving a bright future

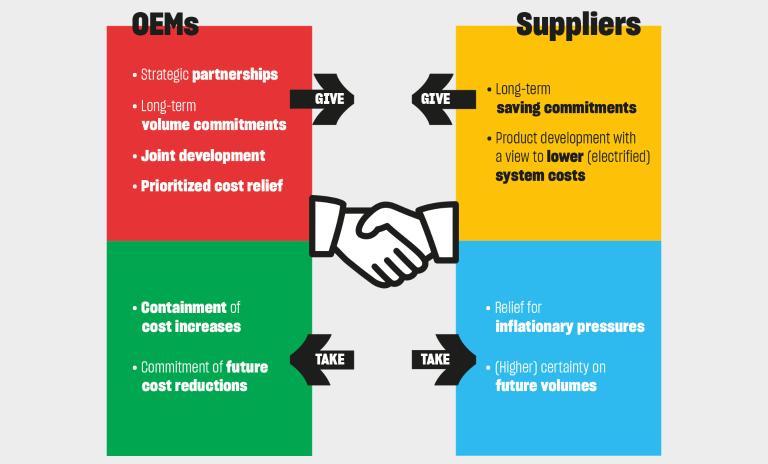

Without a steady supply of EV parts and materials and technological developments in the coming years, performance of the traditional automotive industry will be stuck in reverse. All companies want to avoid zero profitability and OEMs will need to cooperate effectively with Tier 1 suppliers if they want to produce enough EVs to meet long-term demand. Collaboration will help recover higher supply chain costs to secure a win-win situation with healthy profit margins across the entire industry. Gundermann stresses the need for this approach: “There are currently no other long-term initiatives being considered to relieve profit-margin pressures. There is no alternative but to ensure this key partnership works – so the automotive industry can survive and continue to thrive.”

"Gain sharing is key here. We can create a win-win situation even before development begins."

1 - Embrace change

To begin with, the nature of the relationship between automotive OEMs and their Tier 1 suppliers must improve with a deeper level of mutual trust. OEMs have to think strategically towards sustained success rather than short-term gain which pushes suppliers to their limits. A shakeup in the division of labor might be needed to generate greater value from diminished financial and other resources for the next decades. Over 50 years of expertise in ICE vehicle manufacturing will no longer be valid for OEMs switching to EV production – and a demand for different capabilities necessitates newly defined partnerships. Gundermann says, “Tasks which were traditionally always handled by suppliers might be fully absorbed by OEMs in future, but any new allocation of responsibility must be agreed on and clearly stated in contracts drawn up for the next five to ten years.”

2 - Establish loyalty

As current inflationary pressures on Tier 1 suppliers are short-term but detrimental, OEMs could offer them initial compensation to sustain their business. This could secure their source of future production materials as suppliers agree to, for instance, longer-term contracts in return. Realistic strategic commitments for parts supply and purchase could be established, with price models and production volumes agreed in advance and maintained on both sides. Plus, in the short term, as long as OEMs are still producing high-margin ICE vehicles, they are able to pass these additional expenses to their end customers.

For some countries, high inflation is nothing new. In Brazil, for example, inflation has been both high and volatile, with resulting unstable price models for raw materials and parts. Yet the country’s automotive industry is thriving. Roland Berger worked with Brazilian content platform Automotive Business to investigate this by conducting a survey of regional suppliers.

Brazilian Tier 1 suppliers, like those in European and US markets, have faced sharp rises in costs for commodities, freight and utilities in the last few years. To alleviate this financial squeeze, the majority have formed partnerships with their OEM clients to maintain a resilient supply chain by establishing price indexing agreements. However, OEM attitudes vary greatly even within regions, for example, the survey revealed a reasonably high acceptance across some Asian OEMs but very low acceptance by others. A key lesson from this survey, therefore, is that suppliers must approach OEMs with customized collaborative solutions to secure their buy-in for a long-term partnership.

3 - Increase efficiency

Strategic alignment on where to focus on product innovations could be improved to increase resource efficiency and reduce technological risks. Felix Mogge, points out, “In the decade 2010-2020 suppliers primarily invested their resources and capabilities in improving the quality, features and specifications of components they supplied to OEMs. In the next years, we’ll likely see them shift their efforts towards cost-efficiency of products within certain parameters for required functionality or specifications.”

4 - Share insights

Mogge says, “OEMs must be transparent with Tier 1 suppliers and define clear parameters for their technological roadmaps. This way, suppliers can avoid wasted investments in components for features which may never be implemented in new vehicles which reach the market.” This will also eliminate unnecessary price increases for customers, thus keeping OEMs competitive. Mutual benefits can be gained by exchanging access to knowledge and insights from both perspectives. OEMs could help suppliers develop more cost-effective processes in the supply chain. Suppliers could share their specialist knowledge of supply networks and cost structures.

5 - Sustain profits and the planet

Joint commitment to long-term goals will provide advantages for all. Gundermann says, “Gain sharing is key here. We can create a win-win situation even before development begins.” Suppliers handling mass volumes of materials will benefit from economies of scale. OEMs commissioning these orders will gain a portion of these savings. Strategic planning will reduce complexity in supplier management for OEMs and limit operational risks for suppliers. If Tier 1 suppliers invest in materials, parts and technologies, all clearly predefined by OEMs, they can offer their clients a trusted, continual source of resources for focused, large-scale output of electrified vehicles with autonomous features.