A new era is dawning in global business. Roland Berger has the frameworks and tools companies need in order to navigate the coming uncertainty.

Production footprint reloaded

New factors forcing companies to rethink their manufacturing network

The rules of global manufacturing have changed. For decades, the playbook was simple: build production where labor costs were lowest. Today, manufacturing companies face a complex web of factors that are forcing them to fundamentally rethink where and how they produce goods.

"Production networks are being transformed by a new reality where automation, energy costs, and geopolitical uncertainty overshadow traditional labor economics."

The end of an era

In the 1980s and '90s, the math was straightforward. With US manufacturing wages around $15 per hour compared to under $1 in China, production inevitably shifted east. Companies believed globalization would only deepen, trade barriers would fall, and intertwined supply chains were the key to business success.

That belief has proven mistaken. New trading blocs are forming, energy costs are diverging dramatically between regions, and sustainability concerns are rising. Add breakthroughs in automation and AI into the mix, and manufacturing companies find themselves at a crossroads.

Five forces reshaping manufacturing

Our analysis reveals five key factors driving this transformation:

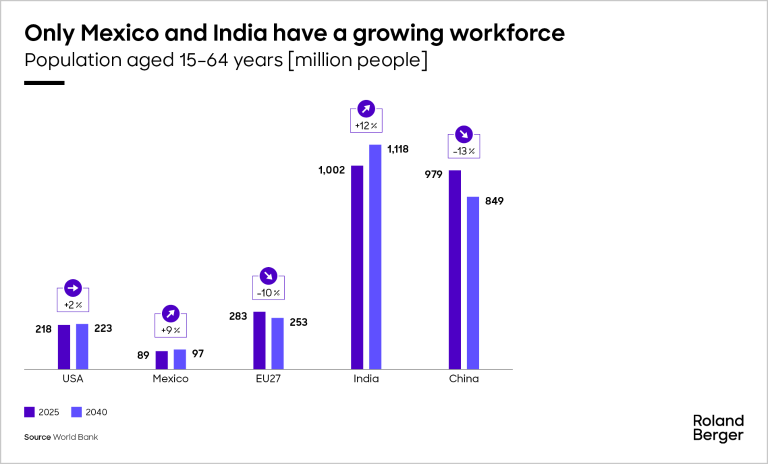

- Labor Markets in Flux: While China and Europe face aging workforces, countries like India and Southeast Asia offer growing labor pools. However, skilled workers remain scarce globally.

- The Automation Revolution: Robot costs have plummeted by 85% over two decades while installations have increased fivefold. This shifting cost equation makes reshoring more viable.

- Energy & Sustainability: European electricity prices have doubled since 2008 and are now 250% higher than in the US and China. Access to renewable energy is becoming a key factor.

- Critical Raw Materials: The energy transition and digitalization are driving demand for rare earth elements and key minerals, with supply often concentrated in specific regions

- Geopolitical Tensions: Growing isolation between regions, trade wars, and strategic competition are forcing companies to reduce dependencies.

A new global manufacturing map

Different regions are pursuing distinct manufacturing strategies:

Asia: China's role is evolving from the world's factory to a strategic player investing globally. Southeast Asia and India are emerging as preferred manufacturing destinations.

North America: The US is seeing strong reshoring momentum, while Mexico's manufacturing sector is booming as companies seek alternatives to direct Chinese imports.

Europe: While facing challenges from economic slowdown, the region is attracting investment in future technologies and seeing a shift from Western to Central European production.

"Properly addressing the uncertainties of geopolitics may well be the biggest challenge when it comes to redesigning a company's manufacturing footprint."

Looking ahead

To navigate this complex landscape, manufacturing companies need new frameworks for decision-making that go beyond simple labor cost calculations. The old playbook is obsolete, but opportunities abound for those who can adapt to manufacturing's new world order.

Companies require a structured approach to optimizing their production footprint. Here, we propose the Roland Berger 3E Footprint Framework, consisting of the modules Envision, Explore and Execute. This leads the company through the necessary steps in the redesign process, from envisioning a clear strategic future vision and investigating key criteria to selecting new sites and managing the transition.

By embracing a structured, comprehensive approach to redesigning their production footprint, manufacturing companies can secure a profitable and resilient future. Understanding tomorrow's world will not only help them navigate these uncertain times – it will position them as industry leaders, ready to thrive in an ever-evolving global market.

Download our full report to discover how leading companies are redesigning their production footprint for this new era.

David Born, Lasse Adler, Philippe Jaspart and Thomas Schwarz also contributed to this report.

Register now to access the full report “Production footprint reloaded - New factors forcing companies to rethink their manufacturing network” and explore transformative manufacturing strategies shaped by global challenges. Furthermore, you get regular news and updates directly in your inbox.

_image_caption_none.png)

_person_320.png)