Economic pressures and changing consumer preferences are reshaping shopping behavior. Our survey reveals a picture of overall optimism with regional variation.

The complex shift to natural ingredients

Critical supply chain considerations to unlock full potential

A notable shift from synthetic to natural food ingredients has become apparent in recent years, primarily driven by consumer demand and heightened regulatory scrutiny. This transition is fueling a robust growth trajectory of approximately 7-8% annually, and has piqued the interest of ingredient producers eager to capitalize on the favorable trends that have come with it.

The transition to natural ingredients is underpinned by several key factors. First and foremost is the increasing health-consciousness among consumers. Second, regulatory bodies are exerting pressure to adopt natural alternatives. The demand for labeling transparency is also growing, and " clean labels " have become a priority for consumer brands. In turn, these brands try to set themselves apart by emphasizing green and ethical claims to reinforce their commitment to sustainability. Finally, technological advancements are helping push innovation in the industry, offering businesses the potential to attract new clients and explore novel applications.

Natural vs. synthetic supply chains

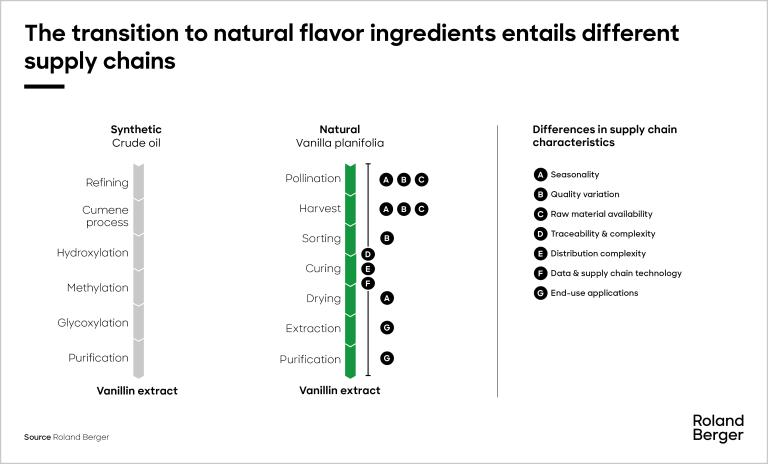

Natural flavor supply chains are fundamentally different from their synthetic counterparts. Take vanillin extract, for instance; it can be synthesized from crude oil or derived naturally from the vanilla planifolia, a flat-leaved vanilla plant. Synthetic production involves industrial processes like refining and hydroxylation, while the pollination, harvesting and sorting in natural production must be done by hand. Consequently, these diverse processes necessitate distinct supply chain requirements. The natural supply chain must accommodate factors such as seasonality, quality variation, raw material availability, and traceability & distribution complexity. Both data & supply chain technology and the end-use of applications are requirements of both production processes, but in comparison natural production requires a vastly different approach.

The supply chains of natural food ingredients see similar differences. For example, synthetic emulsifiers in the form of triglycerides require hydrolysis and glycerolysis, but the natural counterparts involve the production of enzymes from microbial strains or the production of hydrocolloids from the guar plant, which requires harvesting. This means a supply chain characterized by seasonality, quality variation and the availability of raw material.

Characteristics of natural supply chains

The inherent characteristics of natural supply chains can pose challenges for large-scale production. Natural supply chains are heavily dependent on seasonal growing cycles. Quality variations can arise from environmental influence and handling practices. Agricultural yields and geographical or biological factors can therefore limit the availability of raw materials. Natural supply chains also present challenges in traceability and transparency due to decentralized sourcing and a lack of robust monitoring systems. Similarly, natural supply chains are subject to more complex (e.g., specialized storage) and geographically bound distribution lines. Data and technology techniques and operating conditions also vary significantly from synthetic supply chains. Finally, naturally sourced ingredients can contain trace elements that may require adjustments in the end-application.

Mitigating the impact of natural chains

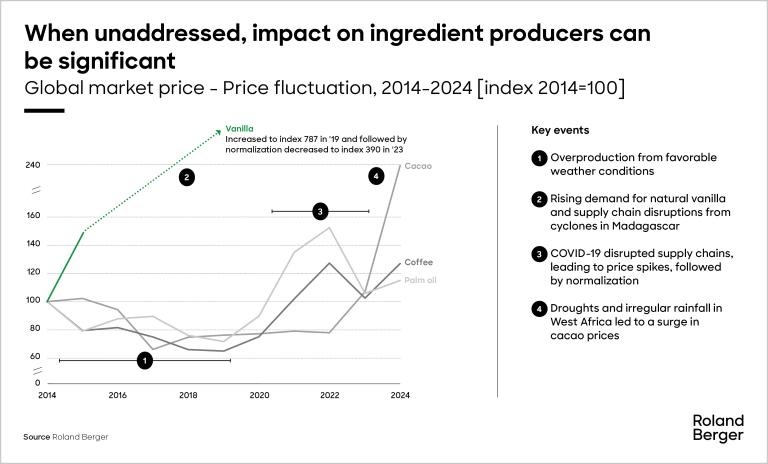

Natural flavor and food ingredients can therefore have far-reaching impact on critical business drivers like price and security of supply. For example, the export price of natural vanilla from Madagascar skyrocketed by almost 700% between 2014 and 2019 due to a combination of rising demand and supply disruptions from cyclones. Similarly, cocoa prices recently surged due to droughts and irregular rainfall, especially in West Africa.

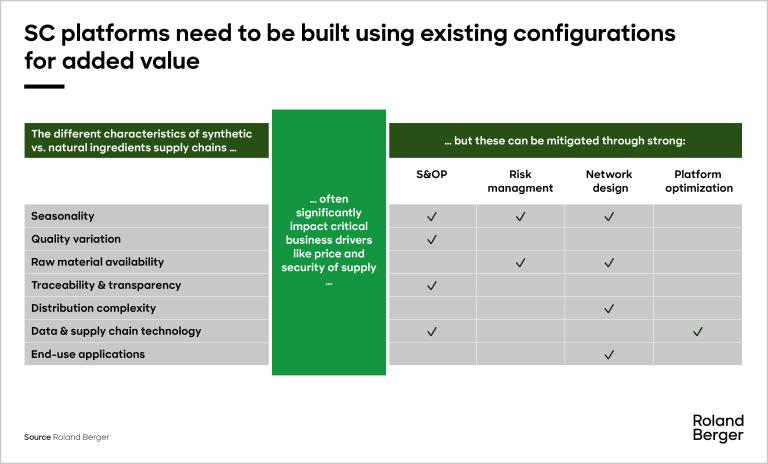

The more precarious characteristics of natural supply chains underscore the importance of proper mitigation. In their switch to natural, ingredient producers must keep a tight leash on their sales & operations planning (S&OP), risk management, network design and platform optimization.

S&OP alignment

Mitigating the vulnerabilities of natural supply chains can start with an S&OP that is squarely in line with the operating model. This enables a clear rule book for tactical planning with robust decision support and a single set of numbers on which to base those decisions. Such alignment will keep the business attuned – and therefore responsive – to market realities.

Proactive risk management

In today’s volatile environment, risk management must transition from a reactive to a proactive stance in order to stay responsive and resilient to the supply chain. This shift involves creating a centralized risk organization that still allows for decentralized, functional risk management practices. A balanced approach combines the inherently cross-functional nature of supply chain risk with central coordination to ensure effectiveness. By prioritizing both short-term supply chain responses and long-term resilience strategies, organizations can better navigate uncertainties and mitigate risks before they escalate.

Balanced network design

Today’s supply networks must strike a balance between global and local frameworks: global supply chains complemented by local networks that address specific market needs. This "glocal" approach allows for a more agile response to both supply particularities and customer demands.

For example, global just-in-time (JIT) strategies can minimize stock levels, with local warehouses and reserves providing a safety net. A shift from a global delivery footprint to a "build where you sell" model can further enhance customer satisfaction. Additionally, focusing on customer-specific variants while pursuing variant reduction can lead to optimized operations overall.

The evolution of supply chain networks should also prioritize sustainable risk management. Companies must be prepared to "expect the unexpected", ensuring that their operations are resilient to unforeseen challenges.

Value-driven supply chain platforms

The optimization of supply chain networks also hinges on the effective use of supply chain platforms. These platforms must facilitate the integration of global and local strategies, allowing for seamless communication and data sharing across the supply chain.

A new era in supply chain management

As we stand on the brink of a new era in supply chain management, aligned S&OP, proactive risk management, balanced supply chain networks and value-driven platforms will be paramount. Such improvements will not only enhance an ingredient producer's efficiency and resilience, but also redefine how the business operates in an increasingly complex and interconnected world. To explore these transformative strategies further and understand how the future of supply chain management impacts your business, please reach out to our experts in food ingredients and supply chain management. They can provide valuable insights and tailored solutions based on their extensive knowledge and experience in navigating ingredient supply chains. We look forward hearing from you.