Navigating rail sustainability challenges with a comprehensive approach for decarbonization and preserving the environment...

The future of innovative propulsion in rail

By Heiko Mosetter and Andreas Schwilling

Battery power in pole position

The ambition to achieve net zero by 2050 is focusing countries’ attention on their transportation sector. Rail is already well ahead of other means of transportation in terms of its climate credentials. But to become fully green, it needs to replace its polluting diesel engines with innovative solutions such as battery or hydrogen propulsion systems. We look at the challenges this involves – from cost considerations to the building of new infrastructure – and consider where each technology can be most usefully applied.

"Given that rolling stock typically remains in service for 30 to 40 years, choosing the right propulsion type is paramount."

Sustainability appears to have slipped down the agenda somewhat in recent political discussions. However, the ambitious CO2 reduction targets established over the last decade or so remain firmly in place: The European Union and the United States both aim to be climate-neutral by 2050, and China by 2060. In the effort to achieve net zero greenhouse gas (GHG) emissions, the transportation sector – a major source of CO2 pollution worldwide – is an obvious focus of attention. Rail is far superior to other means of transportation from an environmental perspective: It is responsible for less than 0.5 percent of transportation-related GHG emissions, having steadily improved its energy efficiency since the 1990s. For example, a long-distance train with electric propulsion emits less than 1g CO2 per passenger-km (35g for regional trains), compared to 166g for an internal combustion engine car and 47g for an electric car. As the greenest mode of mass transportation, rail is a clear climate winner.

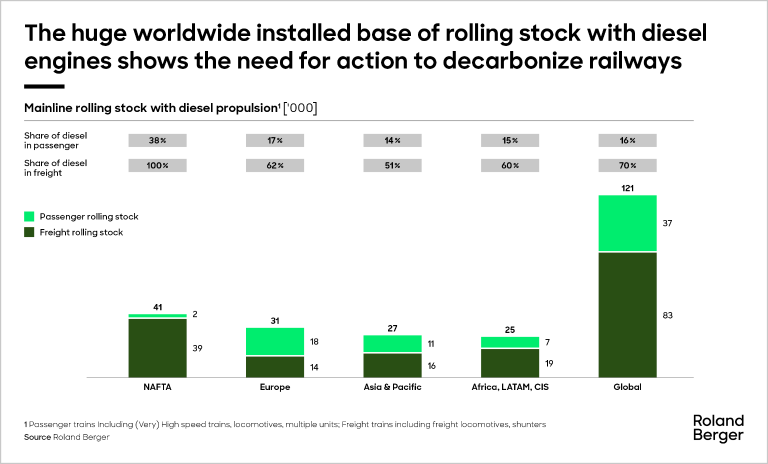

However, many trains worldwide operating on rail networks that have not been electrified are still powered by diesel. In total, roughly 121,000 vehicles – locomotives, shunters and multiple units – still use this form of propulsion. The share of diesel-driven vehicles is particularly high in freight transportation, especially in the NAFTA countries, Australia and Latin America, where large distances are covered by trains without electrification. In the medium to long term, this rolling stock needs to be replaced by vehicles with innovative propulsion systems, to avoid CO2 emissions. But operators cannot put off making the relevant decisions: Rolling stock has a lifetime of 30 to 40 years and units purchased today may be affected by future regulation in the final years of their operation. Indeed, we already see many rolling stock leasing companies (ROSCOs) in continental Europe hesitating to buy new diesel rolling stock.

Innovative forms of propulsion

Three main types of innovative propulsion for rolling stock exist:

- Diesel-hybrid trains combine diesel combustion engines with batteries, partly operating on battery power and partly recovering braking energy. These trains still produce CO2 emissions, but at a lower rate than fully diesel rolling stock

- Battery-powered trains have electric motors and are thus CO2-free. On lines that are partly electrified, some of these trains operate with catenary power (that is, from overhead cables), reducing the size of the battery needed

- Hydrogen trains are generally equipped with fuel cells that generate electric power, which feeds the electric motor. A small battery serves to save recovered braking energy

A number of trains with innovative propulsion systems are currently in use or are being piloted around the world, as shown below.

"On non-electrified sections of track, the limited range of batteries is the raison d'être for hydrogen propulsion despite its lower efficiency."

But it’s not all plain sailing for innovative forms of propulsion. Major challenges remain in the area of cost, as diesel engines are a cost-efficient type of propulsion on lines without electrification. Indeed, the Technical University of Dresden calculates that electrification is only economically justified on lines where two to three trains run an hour in each direction. Below this threshold, current battery-powered and hydrogen trains cost significantly more to operate than diesel – and both regional passenger transportation and freight transportation are highly cost-sensitive areas.

Range issues are also challenging. If there is no catenary, trains must be able to operate without lengthy recharging or refueling periods. If this takes too long, their productivity plummets and the number of vehicles required soars. This challenge applies particularly to battery-powered vehicles. Batteries and hydrogen tanks also require design changes to trains, often involving extra costs. Batteries, for example, add weight to the vehicles, while hydrogen requires significant additional volume for the tank.

In addition, there are the infrastructure requirements. In the case of battery-powered trains, additional charging facilities must be installed where there is no catenary. Hydrogen-powered trains need new refueling stations and a viable supply chain for hydrogen. Maintenance equipment must be adapted for both innovative types of propulsion. Operational reliability is a key requirement for punctuality and customer acceptance. Some hydrogen trains have shown significant problems in this respect – on the regional line RB15 north of Frankfurt (Germany), the transportation association decided to switch back to diesel trains in January 2025 after hydrogen trains experienced substantial operational problems, for example.

Finally, there are problems relating to efficiency. Hydrogen propulsion suffers from significantly lower efficiency due to the additional energy conversion; it is approximately 40 percent less efficient than battery power.

Outlook

We expect to see all forms of propulsion coexisting in the future. The advantages and disadvantages of each type determine where they are best applied. The key factors here are traffic density and range. Thus, electrification of infrastructure (catenary) is generally economically justified for lines with more than two trains an hour in each direction, or three if construction costs are higher. Above this threshold, electric rolling stock under catenary is recommended, which also offers higher traction power. Below this threshold, battery power is more efficient and therefore the recommended option in most applications – putting it in pole position among the innovative, CO2-neutral forms of propulsion.

Range is the deciding factor for battery propulsion. Battery solutions are unlikely to be sufficient for mainline and heavy freight railroads – at least until such time as progress is made on the technological side, increasing battery-powered rolling stock’s range or “autonomy”. In the meantime, battery solutions are more suitable for shunting and short-haul rail freight, and for the many lines where battery-powered trains can operate along certain stretches under catenary and along others with battery power.

Of course, a carbon-free source of electricity is a prerequisite for decarbonization with all the innovative types of propulsion discussed here – even a train running on electricity via catenary emits CO2 indirectly if that electricity is generated from fossil fuels. This also applies to hydrogen produced via electrolysis, which consumes a large amount of electric energy. Most countries need to increase the share of renewable energy in their electricity generation, including creating facilities to story electric energy for periods without sunshine or wind.

For stakeholders, the financial calculations underlying propulsion decisions can be complex. At present, innovative propulsion systems can cost 20 percent or more per train-kilometer than diesel, depending on the line. Capital and operating expenditure (CAPEX and OPEX) over the lifetime of the train or transportation concession must also be taken into account. To accelerate the decarbonization of rail transportation, it may be necessary for politicians to introduce financial incentives compensating for some of the additional costs.

Our consulting services for the rail industry

Whether you are an operator, leasing company/ROSCO or a public transit authority, you need to take crucial investment decisions regarding your fleet strategy. At Roland Berger, we can stand by your side and support you through this challenging process. We offer insights into the market and the latest trends. We can perform a detailed network analysis and evaluate it against coming infrastructure upgrades. We can also run a risk-benefit analysis and help you develop a short, mid and long-term investment plan for your rolling stock, fully tailored to your specific needs. Contact us for a quick review, so we can together reflect on how best to tackle the challenges ahead.

Would you like to know more? Register now so that our experts can contact you for a direct exchange and further information on transportation topics.

_person_144.png)

_image_caption_none.png)

_image_caption_none.png)

_image_caption_none.png)

_image_caption_none.png)

_person_144.png)