These projections for plastic waste to be processed for recycling will open up huge opportunities for those suppliers that can provide suitable recycling technologies and related equipment.

Unlocking profitability in EPC

The untapped potential of SG&A

Companies in the EPC industry have recently strived to secure profitability by improving project delivery to reduce Cost of Goods Sold (COGS). While this has largely been successful, it is now imperative for companies to focus on SG&A expenditure, which has long been overlooked. By critically assessing overhead spending, companies can uncover significant opportunities for improvement, thereby boosting their bottom-line performance.

"While EPC companies have successfully reduced COGS in recent years, many have overlooked the untapped potential in SG&A cost reduction. Refocusing efforts on overhead costs is now imperative for securing competitiveness in an increasingly price-sensitive market."

Over the past few years, the Engineering, Procurement, and Construction (EPC) industry has faced numerous challenges, including not only the COVID-19 pandemic but also persisting geopolitical tensions. These events have led to supply chain disruptions and increased costs, resulting in delays and budget overruns. Not least for projects governed by fixed-price contracts, these developments have made the vulnerabilities of many EPC companies painfully evident. In response, companies have concentrated on improving project delivery by becoming more selective in the projects they undertake to minimize risk and by pursuing operational excellence to enhance execution efficiency. Additionally, a shift from lump-sum/turnkey contracts to reimbursable pricing has helped companies limit their exposure.

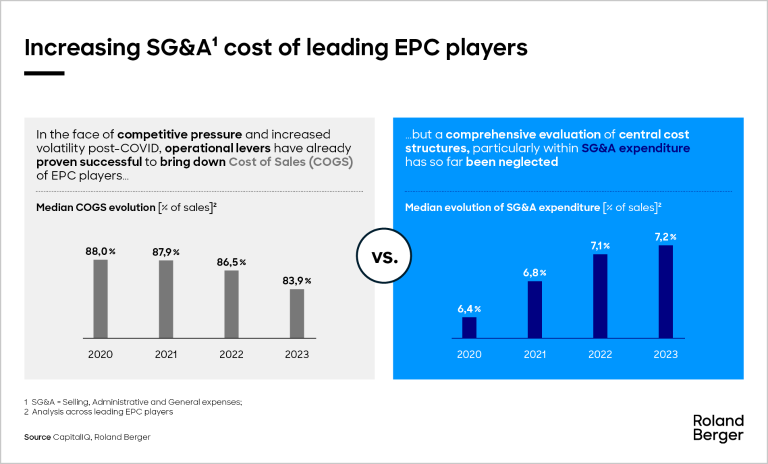

A benchmarking of over 20 leading EPC companies indicates that these strategies have been effective, with the median Cost of Goods Sold (COGS) as a percentage of sales decreasing by approximately 4 percentage points since 2020. While this has helped companies maintain profitability, they have largely overlooked overhead costs, with the median Selling, General, and Administrative (SG&A) expenses as a percentage of sales increasing by about 1 percentage point during the same period.

This rise in overhead costs has offset some of the efficiency gains from the COGS reduction and poses a threat to the future competitiveness in an increasingly price-sensitive market. Therefore, it is imperative for EPC companies to refocus their efforts on reducing overhead costs to secure their position in the industry.

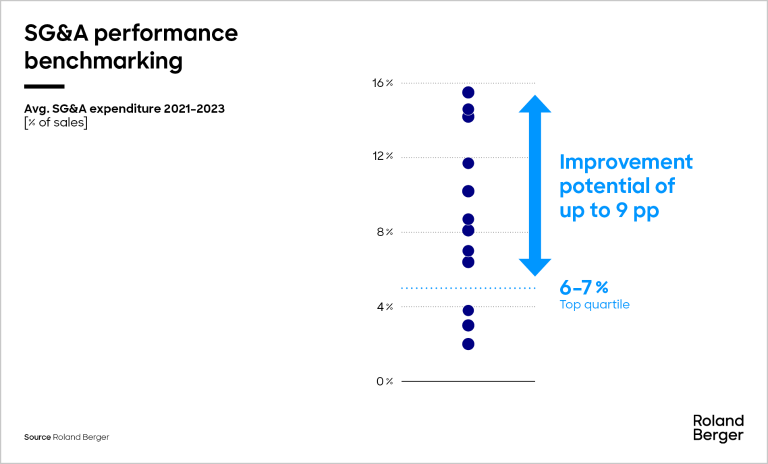

To achieve cost reductions, it is crucial to set ambitious yet attainable targets and derive concrete measures from them. Utilizing outside-in benchmarking to aim for the top quartile of peers can provide valuable insights for quantifying the improvement potential.

Our analysis indicates that leading EPC companies have an SG&A ratio below 5% of sales, with the top quartile trading at roughly 6%. While specific differences in corporate structure (e.g., firm size, HQ location, regional activity, etc.) must be considered, we estimate that an SG&A ratio in the range of 6-7% is achievable for most EPC companies through ambitious target setting and rigorous execution of savings measures.

"Our analysis shows that leading EPC companies achieve lean SG&A ratios, setting a benchmark for the industry. With ambitious targets and disciplined execution, significant improvements are attainable for most players."

Various approaches can be employed to reduce SG&A costs. One of the key levers is streamlining the corporate center, which involves reviewing the structure of support functions such as finance, sales, and IT to eliminate redundancies and optimize resource allocation. Extending the use of shared service centers in best-cost countries for overhead activities like accounting or software engineering offers substantial savings potential but requires careful planning.

Other measures targeting low-hanging fruit offer quick and low-risk savings, such as consolidating legacy real estate structures, renegotiating travel and insurance policies, and optimizing software license usage. However, it is crucial that all savings initiatives align with the company’s future growth objectives to ensure adequate service levels as topline increases.

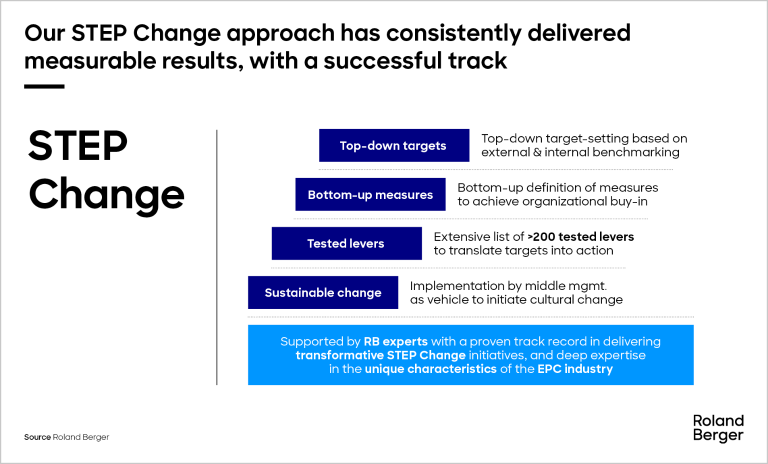

To help clients strike the right balance between setting and implementing ambitious savings targets while ensuring sufficient overhead service, Roland Berger has developed its proprietary STEP-Change approach. This approach has a proven track record of helping clients achieve sustainable cost reductions, particularly within SG&A expenditure within the EPC industry and beyond.

STEP-Change combines top-down target setting with bottom-up measure development. By utilizing various benchmarking tools, achievable savings potential is identified, and targets set accordingly by management top-down. Middle management then collectively develops measures to achieve the savings targets bottom up. This not only ensures organizational buy-in and accountability during implementation but also helps prevent measures from adversely affecting a company’s operations through a decrease in overhead service levels.

Drawing from our extensive project experience, we have curated a comprehensive list of over 200 reality-proven levers for SG&A cost reduction. We have also demonstrated our expertise in navigating implementation challenges to ensure successful delivery.

For more information on how EPC companies can leverage STEP-Change to boost profitability through sustainable cost savings, please reach out to your Roland Berger EPC experts. We look forward to discussing your company’s situation and how STEP-Change can help you in a complimentary “power-hour” consultation.

With contributions from Vincent Haser